We Do It All - And We Do It Well

Our Expertise

AN INDUSTRY LEADER IN EXTRUDED ALUMINUM, FROM START TO FINISH

Extrusion Presses

Extrusion Presses Sizes

- 525 Ton: 2.5"

- 525 Ton: 3.5"

- 1050 Ton: 5.125"

Die cost starting at $985

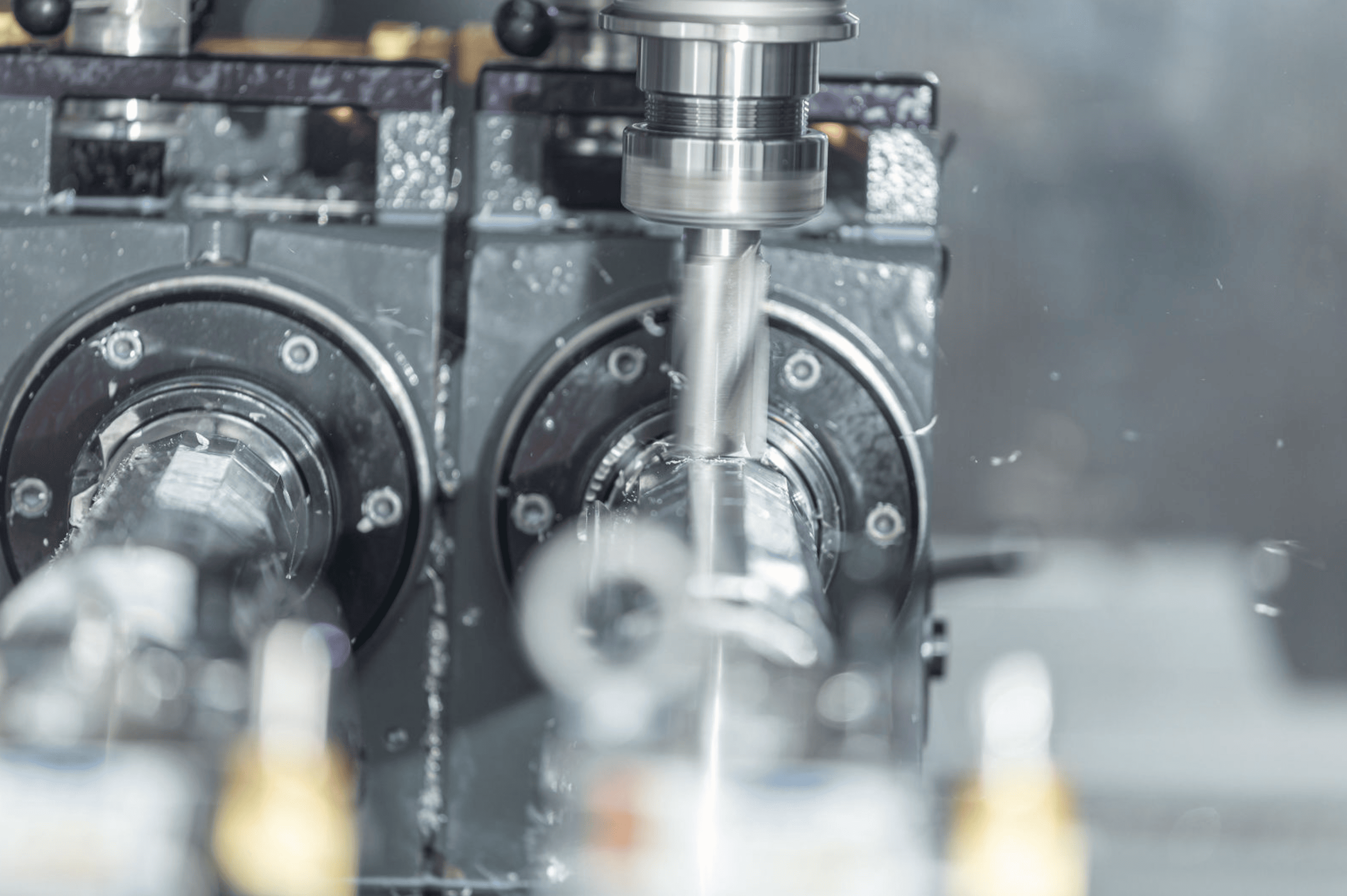

CNC Machining/Fabrication

PSI delivers turn-key parts through a wide range of in-house fabrication services:

- CNC Machining

- Full CAD/CAM capabilities

- OBI Punch Presses

- Hardware Installation

- Custom fixturing for high volume projects

- Quick change vises for efficient set-up on small job

Anodizing

In-house

- Clear Anodizing (Class 1)

- Black Anodizing (Class 2)

- Mechanical Finishes (brushing, polishing, etc.)

- Clear Chromate Finish (Mil-C-5541)

- Etching

- Satin (Type II)

Off-Site Finishing Services

- Class II Anodizing

- Bright Dip

- Wet Paint

Powder Coating

We have a 4 stage inline conveyor system, with a two-man paint station, and a 30' oven for curing up to 12' part lengths.

We also offer off-site powder coat services for part lengths longer than 12'.

Special Packaging

Since your extrusion requirements are custom, shouldn't the packaging be custom as well?

We have a full department specializing in special packaging. Once the packaging is agreed on, the manufacturing/quality plan is updated for repeatability and consistence.

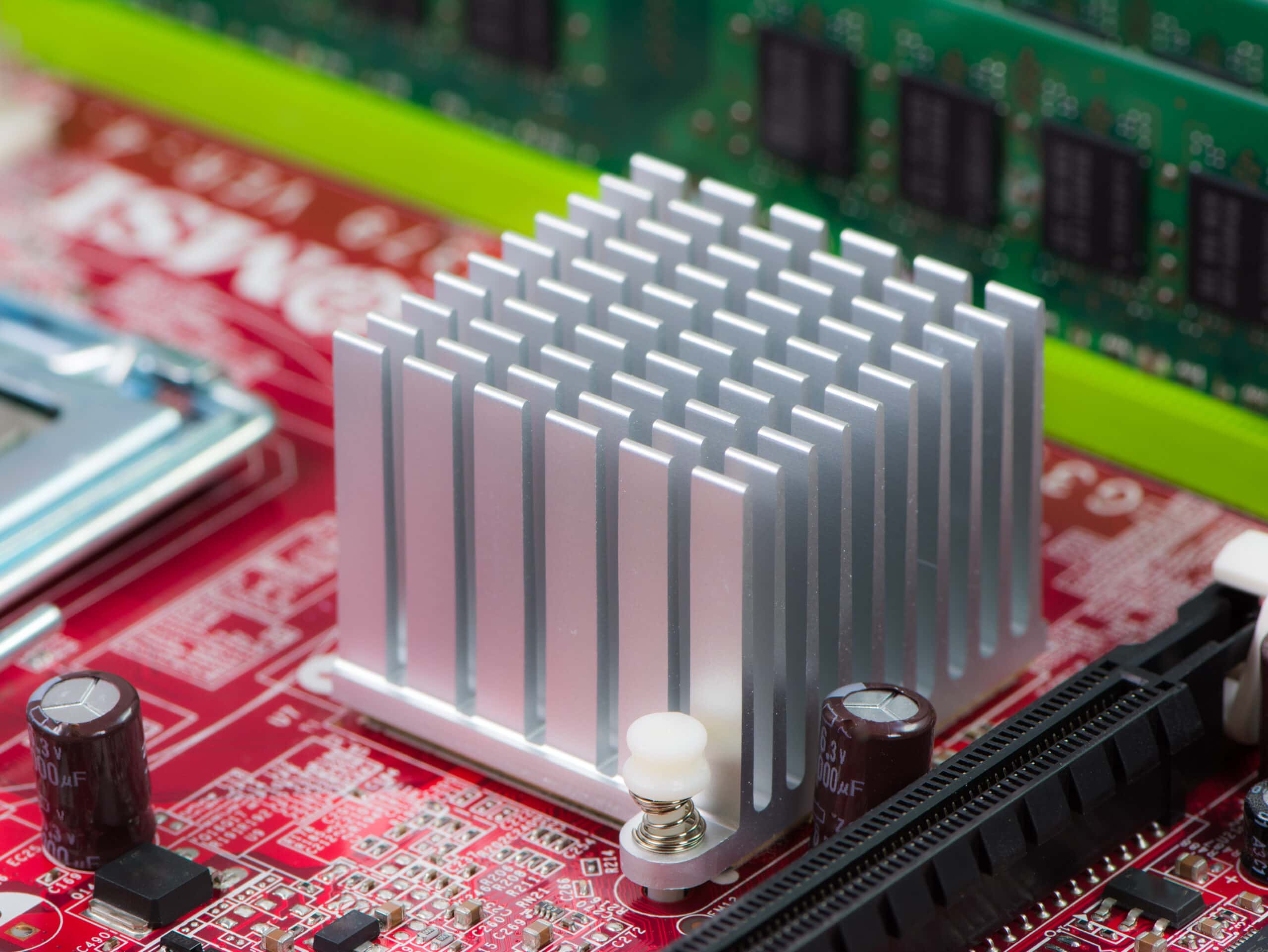

Standard Shapes/Heat Sink

We have standard shapes as well as heat sinks available. Although we do not carry stock, we can typically produce and ship product in 2 weeks.

50 lb minimum on our 3" press

150 lb minimum on our 5.125" press

Assembly

Light assembly including:

- Faceplate labels, gaskets,

- Mechancial hardware installation

- LED Lighting assemblies

- Hardware/Packaging Kitting

Contact Us

At PSI Industries, Inc., we offer a broad range of manufacturing services to provide high-quality aluminum extrusions. Contact us at 972-712-7900 for more information or request a quote related to your next application.

Get in Touch Request a Quote