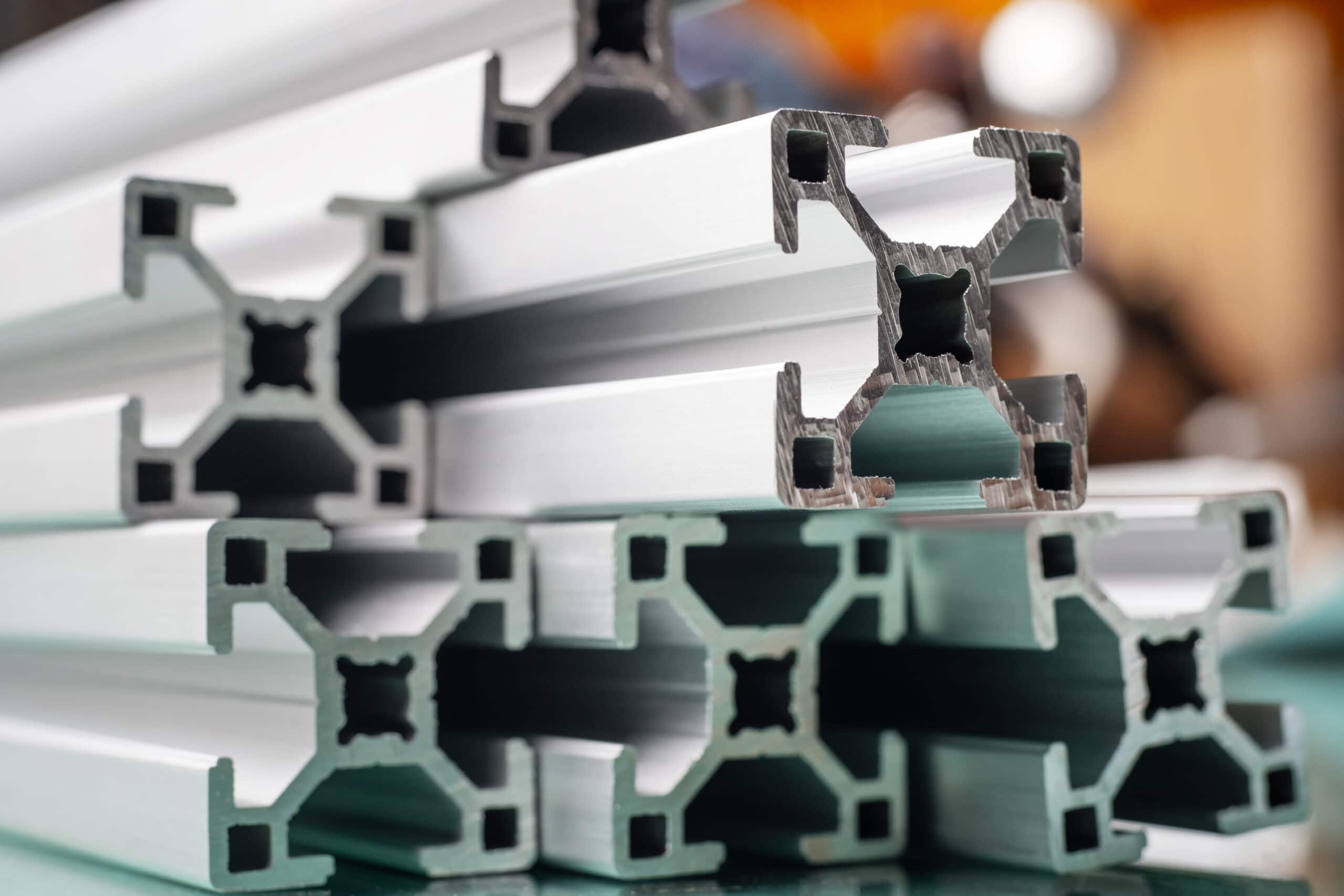

PSI Industries, Inc.’s unique manufacturing capabilities producing turn-key custom aluminum extrusions has positioned us to be an effective supplier all industries

Extrusion Presses

With a focus on quality, we utilize certified materials, advanced handling systems, and automated extrusion presses to create a conducive environment for developing tailor-made precision aluminum extrusions that perfectly align with our customers’ requirements.

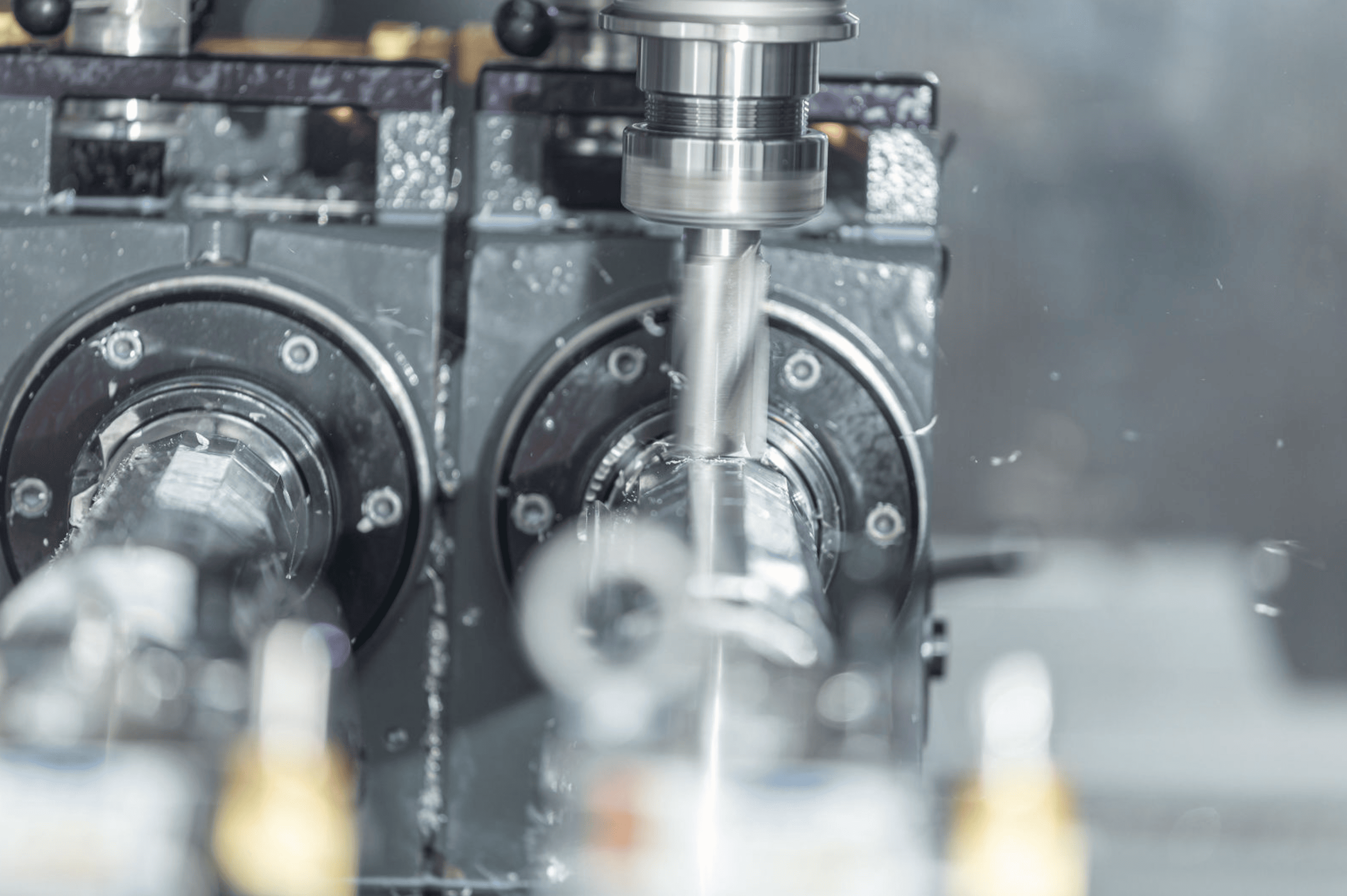

CNC Machining/ Fabrication

We offer a broad range of in-house fabrication services, with our three and four-axis CNC machining capabilities allowing the milling of complex shapes and contours out of various materials with precision, quality, and speed. We also utilize lathes to machine more complicated geometrical pieces.

Anodizing

Anodizing is an electrolytic passivation process often used to increase the thickness of a layer of natural oxide on metal part surfaces. Anodizing improves wear and corrosion resistance, providing better adhesion for glues and paint primers than untreated or bare metal.

Powder Coating

Our four-stage inline conveyor system includes a 30′ oven for curing (up to 12′ part lengths) and a two-man paint station.

Assembly

Our light assembly capabilities include gaskets, faceplate labels, mechanical hardware installation, LED lighting assemblies, and hardware/packaging kitting.

Special Packaging

Once the packaging design is confirmed, our full-service packaging department updates the manufacturing/quality plan for consistency and repeatability.

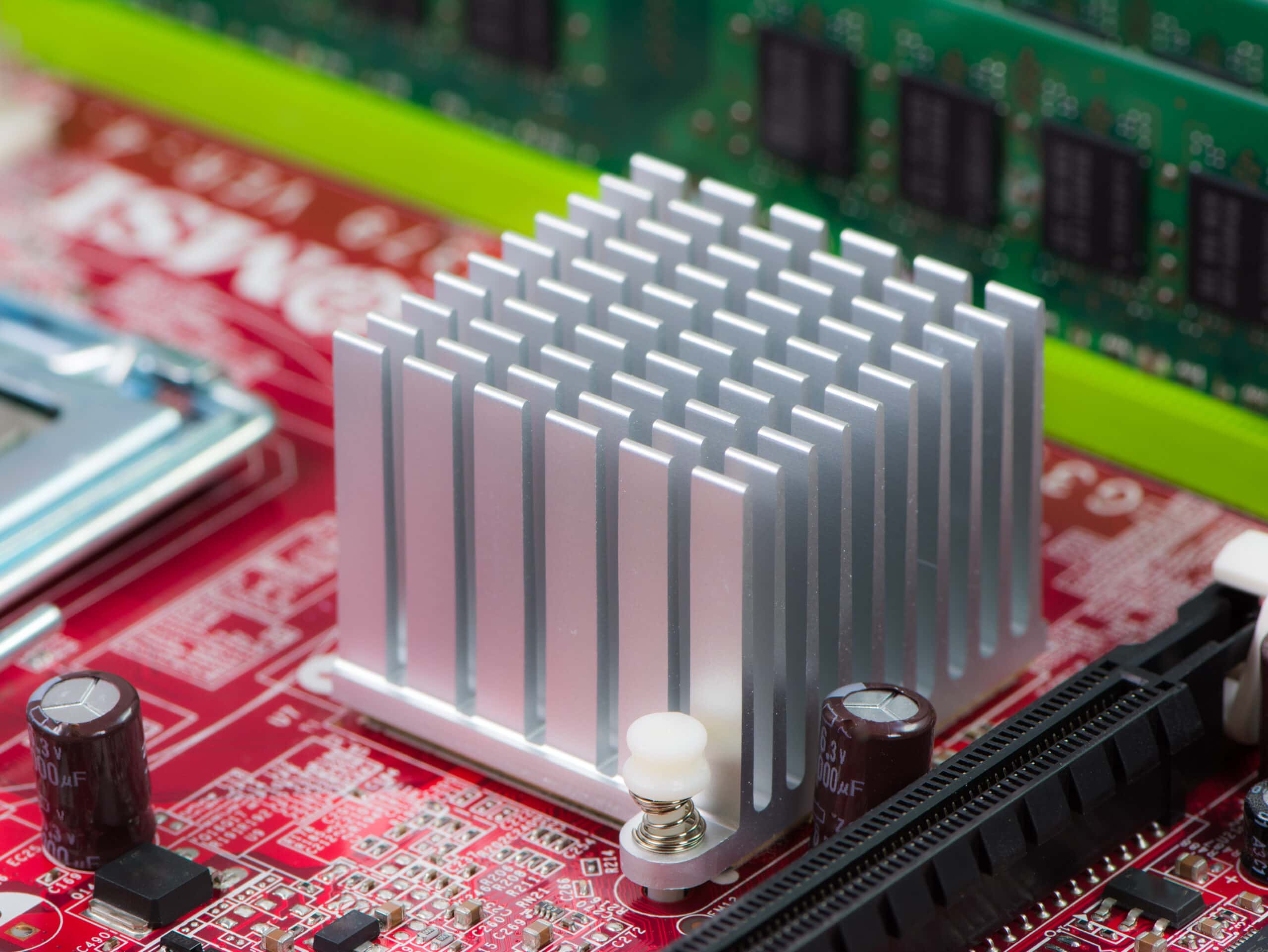

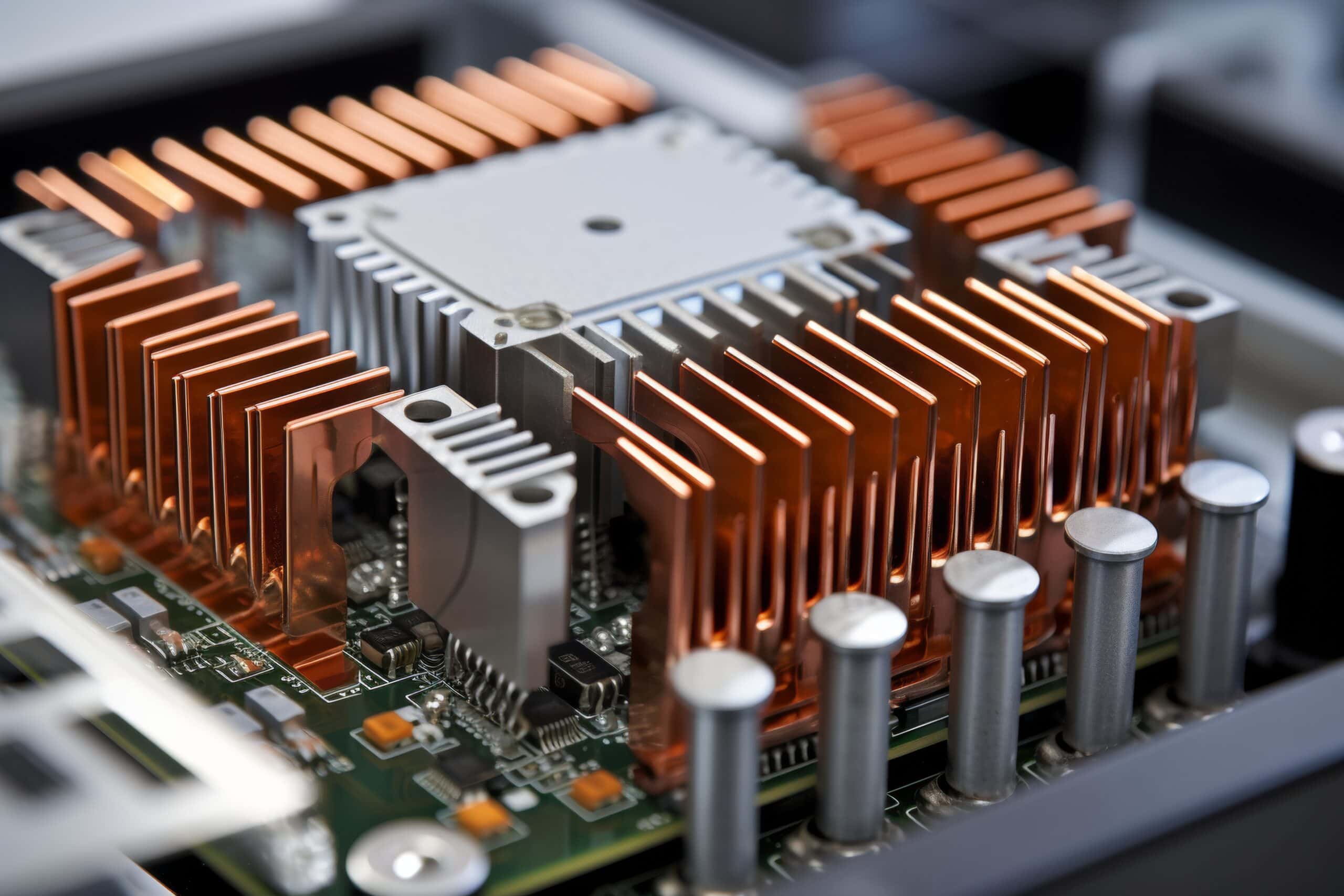

Standard Shapes/Heat Sink

Discover our wide range of heat sinks and standard shapes, crafted to meet your specific requirements. While we don’t maintain a stock inventory, we can swiftly manufacture and ship any product within a two to four week timeframe.

Custom Aluminum Heat Sink Manufacturer

PSI Industries is a custom aluminum extruder and fabricator dedicated to exceptional customer service and product quality. As an ISO 9001:2015-certified company, we ensure every product meets the highest standards of quality and efficiency.

Aluminum Fabrication Services

PSI Industries is a custom aluminum extruder and fabricator dedicated to exceptional customer service and product quality. As an ISO 9001:2015-certified company, we ensure every product meets the highest standards of quality and efficiency.

Aluminum Sign Extrusions

PSI Industries, Inc. is a trusted ISO 9001:2015-certified manufacturer specializing in custom aluminum extrusions and fabrications.

Aluminum Stamping & Extrusion Services for Low-Volume Orders and Prototyping

PSI Industries is an experienced, full-service provider of extruded and CNC-machined aluminum parts and components.

Reshoring Manufacturing Services

When a company decides to reshore its manufacturing operations to the US, it’s important to transfer those services to a reliable and experienced partner.

Benefits of Working With Us

People

Our team has extensive experience in manufacturing. We regularly assist our customers by getting involved in the initial stages of product design to create custom extrusions using the proper alloy. This interaction helps ensure the development of cost-effective, quality products.

People

Secondary Processes

Unlike many aluminum manufacturers that only manufacture aluminum extrusion profiles, we provide an extensive range of custom fabrication and CNC machining services, acting as a one-stop shop for aluminum products.

Secondary Processes

Quality

We always strive for the best quality to ensure clients receive superior aluminum products. Our team pays attention to every detail, focusing on best practices when developing extrusion shapes design, fabrication, extruding, surface finishing, final assembly, and packaging.

Quality

Cost Savings

Being vertically integrated, we manufacture custom parts ensuring our clients receive the best price for any project.

Cost Savings

Industries We Serve

Whether designing a simple extrusion to hang paintings or an engineered system for the construction and building trade, we have the experience and knowledge to help your design team with a wide variety of products. We work with many industries, which include:

Trucking & Automotive

Lighting

Durable Consumer Goods

Distribution

Awning & Signage

Marine

Recreational / Outdoors

Medical & Health

Instrumentation

ISO 9001:2015 Certification

In 1995, we first obtained ISO registration and are certified to ISO 9001:2015 today. We incorporate state-of-the-art metrology with our quality systems to ensure we meet or exceed our customers’ expectations.

At PSI Industries, Inc., we firmly stand behind our commitment to quality and will do whatever it takes to meet the demands of consistency and quality every time.

Contact Us

At PSI Industries, Inc., we offer a broad range of manufacturing services to provide high-quality aluminum extrusions. Contact us at 972-712-7900 for more information or request a quote related to your next application.

Get in Touch Request a Quote